Milk poured down the drain, acres of fresh produce ploughed up, and sheep’s fleeces burnt or composted. These have been just some of the heart-breaking scenarios faced by farmers over the past few years.

Recent times have been challenging for many industrial and hospitality sectors, but for agriculture there has been a triple whammy of problems. Brexit, poor weather and the pandemic have together resulted in the loss of nearly a billion pounds from the UK’s farm income. This was difficult for large-scale farms, and potentially devastating for small ones. The dramatic fall in income for many farms has led to a large number going out of business, and survival has only been made possible by soon-to-be-cut subsidies.

Despite the wonderful properties of sheep’s wool, the burning or disposal of it is not a new thing. In a fast-fashion world of petroleum-based polyester and nylon, this beautiful natural fibre is now considered practically valueless. The pandemic added to the challenges, with remaining demand for wool products vanishing. For example, wool carpets are normally replaced very frequently on cruise liners and in hotels.

Fleeces must still be removed from sheep for welfare purposes, but the cost of transport often makes it more cost-effective to destroy them.

It is against this backdrop that Jenn Monahan works. A self-confessed wool obsessive working from a tiny workshop in Norfolk, England, she has a simple aim: to bring value to a waste product and to do it sustainably. By producing yarn and other products from wool, she is supporting small-scale farmers and restoring interest in an underappreciated material.

It’s a blustery, mild day when I arrive at the fibreworkshop. Monahan shows me the garden, where she grows plants for dyeing the yarn. Nothing is wasted. Fleece not suitable for yarn is used as a mulch covering the soil, to reduce weeds, retain moisture and provide nutrients. The smell of lanolin fills the air.

The workshop is peaceful, containing an array of tonally perfect, naturally dyed yarns. The colours are so desirable that I start imagining the blend for my ideal jumper. Monahan welcomes people. She wants to share her knowledge and to help others learn about the whole process.

Her background previously working in climate science means that she has the knowledge and desire to work in an ecologically sound way. “My aim”, she explains over a cup of tea in her cottage, which is heated only by wood, “is to produce a traceable, sustainable yarn with zero waste, as well as bringing positive regenerative impacts to this struggling industry.”

These are bold claims for such a humble approach, so let’s follow the thread right back to the start of the story.

The sheep

Rare breed fleeces are often considered to be less valuable than those from mainstream breeds, yet Monahan chose to focus on the Norfolk’s rare indigenous sheep breed, the Norfolk Horn. Often flocks are very small, so she works with several local farmers. She selects only those with the highest welfare flocks: those leading very natural, grazing lives with low ecological impact. She explains: “For people, our diet and lifestyle show in our hair, and it’s the same for sheep. You can tell a fleece that has come from a healthy sheep because of the quality of the fibres and the feel of the wool. It means happy sheep are vital.”

Small-scale farmer Kirstie Perfitt farms in Norfolk with her husband Graham, and supplies Monahan with fleeces. “We have a flock of 70 sheep,” she tells me. “I fell in love with the breed – they are such characters and surprisingly elegant, like deer. I always think other sheep are boring compared to the Norfolk Horn, which are a bad-mannered, characterful bunch.”

The sheep lead a grass-fed, low-stress life and need shearing each year. “Before,” says Perfitt, “we just didn’t know what to do with the fleeces and ended up storing them in the barn. It wasn’t commercial to sell them, but I hated the waste. We were so happy to meet Jenn and be part of her mission.”

The fair price

Small producers with limited resources can find themselves unable to participate in the UK’s British Wool co-operative market system. As an alternative, Monahan pays well above the British Wool market value for each fleece and ensures that local craftspeople earn more than the living wage.

The process

Traditional plants are grown to dye the yarn – from woad for the blue colour, to chamomile for yellow, to madder for reds and pinks. Monahan’s dye garden provides most of what she needs and ensures that all the dyes are natural and entirely plant-based. There is no waste in the dyeing process. Leftovers can be composted and remain in the circular system. Monahan believes there is no such thing as waste – only a lack of imagination! The overall carbon footprint is low, with 100% renewable energy used.

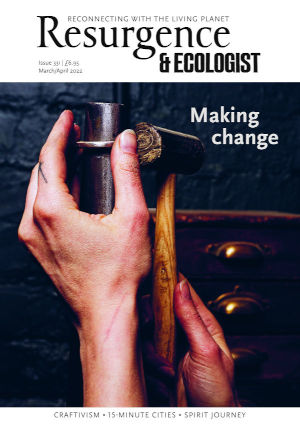

The quiet activism

There’s a quiet magic to Monahan’s brand of gentle activism. At events and in workshops, people are attracted to the beautiful, colourful yarns, but then are drawn into conversations about climate change, the small-farming crisis, sustainability, waste and microplastics. “In fact, I feel like I’ve done more to change people’s minds than when I used to work as a scientist in climate change. Sometimes a soft approach is best.”

There is no denying that this is happening on a small scale that can seem like a mere drop in the ocean compared to the global problems we face. Yet this example of one person making a difference, living thoughtfully in keeping with sustainable values and actually doing something about a problem, while sharing the ethos, is inspirational, whatever the scale. After all, no natural resource should be wasted.

Follow the Perfitts and their sheep on www.instagram.com/straightfromthefield

Find out more about the fibreworkshop at www.fibreworkshop.co.uk